SMGRQ-Z Intelligent Motor Soft Starter Series

Detailed introduction:

Product description

SMGRQ-Z series of intelligent AC motor soft starter is the use of power electronics technology, microprocessor technology and modern control theory design and production of the current international advanced level of new motor starter equipment. The product can effectively limit the starting current of asynchronous motor starting, can be widely used in fan, water pump, transmission and compressor and other heavy-duty load equipment, is the traditional star / delta conversion, auto-buck, Voltage starting equipment ideal for the new generation of products.

Model meaning

Performance advantages

○ reduce the motor starting current, reduce the distribution capacity, to avoid investment in capacity;

○ reduce the starting stress, extend the motor and related equipment life;

○ smooth start and soft stop to avoid the traditional starting equipment surge problem, water hammer effect;

○ A variety of start-up mode and a wide range of current and voltage settings, can adapt to a variety of load situations, improve the process;

○ perfect and reliable protection, more effective protection of motor and related equipment safety;

○ can be used for frequent occasions, stop the occasion.

Working principle

SMGRQ-Z series motor soft starter with three pairs of anti-parallel thyristor in series AC motor stator circuit. The use of the role of the electronic switch thyristor through the microprocessor to control the firing angle changes to change the opening degree of thyristor, thus changing the motor input voltage to achieve the purpose of controlling the motor soft start. When the start is completed, the soft starter output reaches the rated voltage.

Then through the bypass control signal, automatic control three-phase bypass AC contactor (KM) pull, the motor into the power grid operation, as shown in Figure

Typical Application Brief

Water pump - - The use of soft stop function, stop the water hammer to alleviate the phenomenon of the pump, saving the cost of system maintenance.

Ball mill - the use of voltage ramp start, reduce the gear torque wear, reduce maintenance workload, that saves time, but also save money.

Blower - reduce belt wear and mechanical shock, saving maintenance costs.

Compressor - - use of current limiting, to achieve a smooth start, reduce motor heating, extend the service life.

Crusher - the use of stall protection and fast protection, to avoid mechanical failure or blockage caused by motor overheating and burned.

Conveyor - Soft start to achieve a smooth and gradual starting process to avoid product displacement and liquid spillage.

Features

○ Using high-performance microprocessors, anti-interference ability, stable performance.

○ Six kinds of starting modes: voltage ramp start, current limiting start, jog start, current ramp start, ramp + current limiting start, kick + ramp start. Applicable to a variety of load types, to achieve the best starting results.

○ Two kinds of parking modes: free stop, soft stop.

○ Two operating modes: running to allow the opening of the thyristor and prohibit the opening thyristor can be set to select.

○ Overload protection, over-temperature protection, communication interruption, time-out of start-up time, three-phase current of motor over-current, over-current, over-current, over-current, over-current Balance (can be set unbalanced), overload (6 overload levels, can be set) and so on. And can query the last three fault records, providing fault analysis basis.

○ A variety of detection functions: A, B, C three-phase current detection.

○ This product comes with 4 ~ 20mA analog output, Rs485 communication interface (using MODBUS-RTU communication protocol), you can enter the PC through the parameter settings, operation and monitoring, to achieve high intelligent control.

○ The parameters of the soft starter can be set through the keyboard, the keyboard can be hot-swappable in the power state, and has a keyboard parameter download, soft starter parameter upload function.

○ Chinese LCD display interface: soft starter can display the different working status.

○ A variety of output functions: bypass output, fault output, programmable relay (action stage can be set).

The environment used

○ Power supply: city power, self-provided power station, diesel generator set;

○ Input voltage: AC380V, AC690V, AC1140V (-10% ~ + 15%), 50Hz / 60Hz;

○ Applicable motor: general squirrel-cage induction motor (please refer to the order of the winding motor);

○ Starting frequency: Standard product is recommended to start and stop less than 20 times per hour;

○ Cooling: natural air cooling;

○ Installation: wall-mounted;

○ Installation requirements: SMGRQ-Z series soft starter should be used with bypass AC contactor;

○ Protection class: IP20 ~ IP30, depending on the power level to determine;

Environmental conditions: altitude of more than 1000 meters, corresponding to reduce the capacity to use; ambient temperature between -25 ℃ ~ +45 ℃; relative humidity does not exceed 95% (20 ℃ ± 5 ℃); condensation, no flammable, explosive , Corrosive gases, non-conductive dust. Indoor installation, well ventilated. Vibration is less than 0.5G.

Control mode

SMGRQ-Z series soft starter total of the following six start mode, the user can choose according to their load conditions.

1: voltage ramp start; 2: current limiting start; 3: jog start; 4: current ramp start; 5: ramp + current limiting; 6: kick +

○ Voltage ramp start

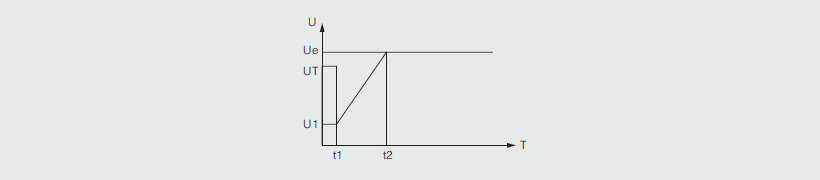

After the start, the soft starter output voltage, quickly rose to "ramp start initial voltage" value U1, and then according to the "voltage ramp start time" gradually increase the output voltage until the start is complete, as shown.

Voltage ramp start method for large inertia load, or the starting current requirements are not strict, but the starting stability of the higher requirements of the occasion. This starting method can greatly reduce the starting impact and mechanical stress. The greater the initial voltage U1, the greater the initial starting torque, but the greater the instantaneous impact of the start, the length of the starting process and the starting time set the value and the severity of the load, and the current limit has nothing to do.

○ Current limiting start

After the start, the motor current rapidly rises to the set current limit value Im, and keep the output current is not greater than this value, the motor gradually accelerated, the voltage gradually increased, when the motor is close to the rated speed, the motor current rapidly dropped to rated Current Ie, complete the starting process, as shown below.

Current limiting start mode is generally used in the starting current has strict requirements of the occasion, especially the grid capacity is too small, to limit the starting capacity, according to the requirements to set the current limit factor, generally between 2.5 to 3 times, set Too small will not be able to start normally. When starting with current limiting, the starting time is related to the current limit factor. The larger the current limit is, the shorter the starting time is, and the smaller the current limiting factor is, the longer the starting time is.

○ Jogging starts

The output voltage of the soft starter increases rapidly to the jogging voltage U1 and remains the same, changing the set value of U1 can change the output torque of the motor when starting jogging, the function of the test or

Some of the load location is very convenient, as shown below.

○ Current ramp start

After starting, the starting current will rise gradually according to the set current ramp start time until the start is completed. When the starting current reaches the set current ramp multiple, the current will remain unchanged until the start is completed.

Current ramp start is generally used to speed up the requirements of faster load or synchronous speed higher motor.

○ ramp + current limiting start

The motor voltage rises according to the slope set in advance, but if the current exceeds the current limit value, the boost is suspended, as the motor speed increases, the current falls below the current limit, and then continue to linear boost to full voltage , Start complete, as shown below.

This starting method is mainly used for the power supply capacity is small and requires starting the impact of the smaller load.

○ sudden jump + ramp start

For some static resistance of the load, the starting moment requires a larger torque, but also the normal start, you can choose this starting mode. When starting, the soft starter instantly outputs a higher voltage (time can be set), the motor rotation, and then press the voltage ramp start mode start until the start is complete, as shown below.

This starting method is mainly used for static resistance of the load.

Stop mode

Freewheel stop: When the shutdown command is received, the soft starter control bypass contactor is disconnected. At the same time, the output voltage of the main circuit thyristor is blocked, and the motor is gradually stopped according to the inertia.

Soft stop: In this shutdown mode, the motor power supply from the bypass contactor to switch to the main circuit thyristor, control the output voltage gradually reduced until the motor smooth shutdown. Soft stop time: 0s ~ 60s

Overload protection level and selection

○ Motor overload protection is set by the electronic overload protection level parameter.

○ Electronic overload protection level is divided into 1-6, the higher the level, the more stringent protection, the lower the level of protection more sensitive. Users can set different protection levels depending on the severity of the load. The higher the level, the heavier the applicable load. And in the same protection level, the soft starter at start and finish the motor overload trip time is different, the soft starter in the start, run, soft stop process, the specific standard overload protection level and action trip time, See the table below

○ Starting process Overload level Default: 5 level

○ Run Overload Level Factory Setting: Level 2

○ Motor overload protection characteristic level (180 seconds when the thermal state is restored to the cold state)

Operation keyboard

SMGRQ-Z series soft starter with 122 × 32 dot matrix LCD display module or LED digital tube and silicone keypad operation display keyboard, Chinese display mode, 6 micro-button, soft starter can achieve the starting and stopping operation , Parameter setting, modification, fault query, fault reset and other operations. See the figure below.

Terminal Wiring Diagram

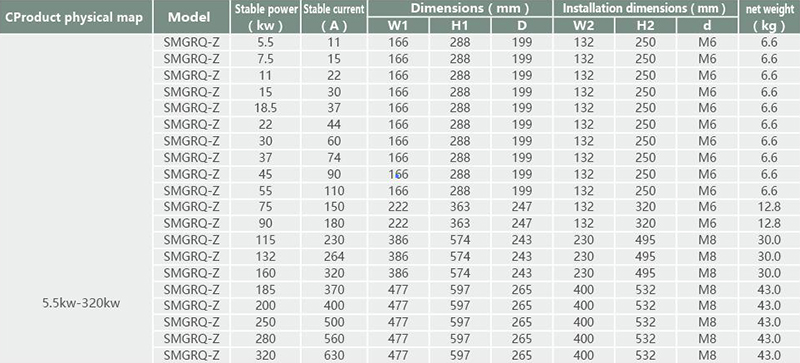

Dimensional structure drawing