SMGTR Electrical Fire Monitoring System

Detailed introduction:

Scope of application

SMGTR electric fire monitoring system is the electric fire early warning and monitoring as the main purpose, the use of digital technology, the introduction of distributed design of a new generation of electrical fire monitoring system. The system has passed the National Fire Electronic Product Quality Supervision and Inspection Center of 3C mandatory certification, can be applied to large shopping malls hotels, public buildings, intelligent buildings, petrochemicals, industrial and mining enterprises and other dangerous fire occasions.

SMGTR electrical fire monitoring system can be installed in TN-S, TN-S-C and local TT low-voltage distribution system, the system includes SMGTR electrical fire monitoring equipment, SMGTR electrical fire monitoring detectors and residual current transformers, temperature sensors and other accessories. The electric fire monitoring detector is used to monitor the parameters such as the domain current, the load current, the cable temperature and so on in the monitoring circuit, simultaneously uploads to the monitoring equipment to realize the centralized control and the centralized management; When the correlation parameter is abnormal in the circuit, the monitoring equipment sends out the sound and light alarm, , While the site detector sound and light alarm and control signals, to remind users to conduct investigation or replacement of hidden lines, reducing the risk of electrical hazards caused by the fire.

System functions

○ Real-time monitoring:

System real-time monitoring of the residual current and temperature of each loop, and in the main interface shows the details of the contents of the circuit name number and various types of function buttons.

○ Alarm setting and prompt:

The system supports the remote current and temperature alarm values and various loop information and status of remote settings. When the loop alarm occurs, the system sends out sound and light alarm signal, while the interface sends significant color change, and automatically record the details of the order of events, event record retention ≥ 24 months, million trace.

○ Alarm and fault record:

The system is equipped with a dedicated historical database, providing historical alarm records and historical fault records. Users can access, query and print at any time through the report interface. Advanced users can delete the records one by one or all.

○ Alarm printing:

Monitoring equipment is equipped with micro-printer, can automatically / manually print the alarm, fault information. Supports automatic printing of information by setting the interface to alarm / fault occurrence.

○ Historical Data Trend Curve:

System for the history of the residual current and temperature data, support the curve of the query, query time interval and loop can be dynamically set. The interface can reflect in real time the surplus electric current or the temperature range of change in any period of time.

○ Status information display:

The system can display the current status information (power status, equipment failure status, alarm status and working status of all current communication devices) in real-time and keep in sync with the monitoring device indicator.

○ System failure self-test:

Real-time display of internal monitoring function of the functional module and has a fault self-diagnosis function, while real-time display system fault causes, and real-time regional probe to determine the state of communication, the entire system failure intelligent self-test.

○ user classification management:

The system is divided into three levels of authority management, different operations need corresponding permission level to be operated, in order to prevent misoperation and illegal entry.

○ System operation information:

The system has a separate information window, record all the running information of the equipment since the start and run, and then judge the current state of the running system.

System structure

SMGTR electric fire monitoring system uses equipment layer, communication layer, the management of three-tier distributed design, decentralized control, centralized management.

For regional monitoring of large-scale regional multi-level monitoring equipment can be cascaded to achieve the operation and set the system and sub-regional display, alarm.

For small and medium-sized regional monitoring using a single monitoring device to achieve the overall monitoring system, the installation area of the detector signals all sent to the monitoring equipment, centralized processing, centralized display, alarm and management, the system cost-effective.

Scope of application

It can be used in the detection of leakage current, cable, cable terminal and intermediate joint. It can be used in

factories, mines, institutions, schools, shopping malls, hotels, entertainment places, residential buildings and family houses. Cable joint and intermediate joint temperature detection.

Model and meaning

Adapt to the working environment

○ Ambient temperature 30 ℃ ~ +70 ℃

○ Relative temperature 10 ℃ ~ 70 ℃

○ Altitude ≤ 3000m

Working principle

Electric fire monitoring detector real-time monitoring of low-voltage power distribution system in the live wire to ground fault generated residual current and distribution box or cable temperature to determine the cause of electric fire hazards and early warning.

When the power distribution circuit is in normal operation, the loop current through the residual current transformer (LF) current vector sum is zero (regardless of the circuit inherent leakage current), the residual current value is zero, and the temperature in the normal working range, detector (SMGTR ) Running in the monitoring state.

When leakage occurs in the circuit, the real-time residual current value is monitored by the detector (SMGTR) by the residual current transformer (LF) current vector sum is not zero. If the residual current value is greater than the set protection value, the detector sound and light alarm signal, and through the release (K) automatically cut off the fault circuit power supply. The detector (SMGTR) monitors the temperature of the circuit in real time through a temperature sensor (PT). When the circuit temperature is abnormal, the detector (SMGTR) monitors the temperature value is greater than the set protection value, the detector sound and light alarm signal, and through the release K automatically cut off the protection line power, thereby reducing and reducing electrical fires To ensure the safety of life and property, electrical fire detectors can be connected to the fieldbus electrical fire monitoring equipment to achieve multi-loop centralized monitoring.

S1 S8 terminal arrangement

SMGTRl-S8-type (8) wiring diagram

Mounting dimensions (mm)

Model and meaning

Single-channel controller external wiring

Technical Parameters

Model and meaning

Features

○ Low-power CUP core embedded high-performance integrated touch screen, embedded operating system platform;

○ Configuration monitoring software, two operation permission settings, easy management; real-time monitoring, accurate positioning alarm point;

○ Optional 4/8-way CAN communication interface, can connect 128/256/512 monitoring detectors;

○ with sound and light alarm and display alarm loop, support mute, self-test function and reset function;

○ own printer, easy to print alarm records;

○ Self-backup power supply, to ensure continuous power supply within 4 hours.

○ 2-way relay output, 1 switch input, optional 1-way RJ45 Ethernet digital interface, with 24V power supply, convenient and automatic fire alarm system connection;

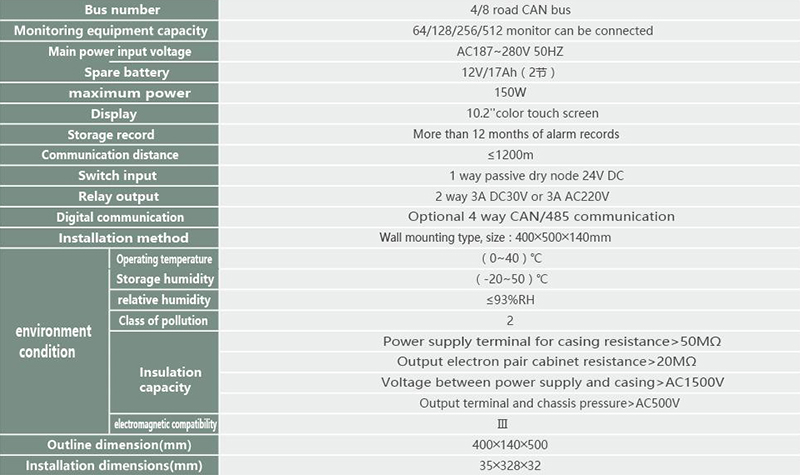

The main technical parameters

Model and meaning

Features

○ High-performance PC as a hardware, using a dedicated operating system;

○ Optional 8/16/24/32 way CAN communication interface, can connect 256/512/768/1024 monitoring detectors;

○ With sound and light alarm function, support mute, self-test function and reset function;

○ 2-way relay output, 1-way switch input;

○ Three-pole operation authority setting, easy to manage;

○ own printer, easy to print alarm records;

○ Self-backup power supply to ensure continuous power supply within 4 hours.

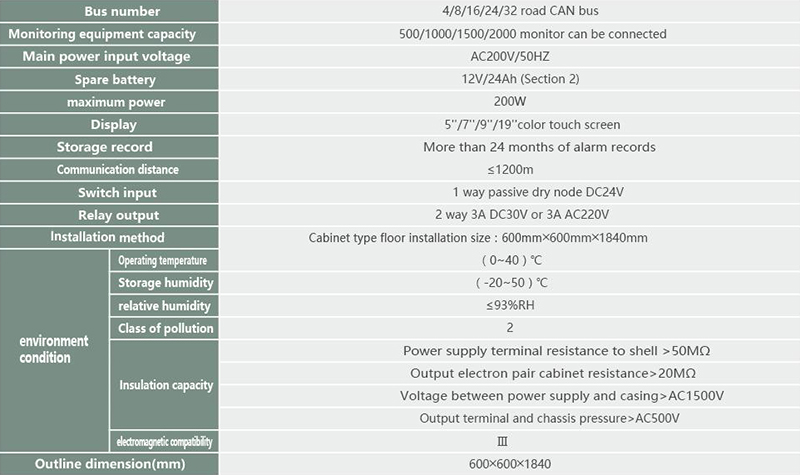

The main technical parameters

Model and meaning

Features

○ With the electric fire monitoring detector to measure the residual current use;

○ Measuring range 30 ~ 1000mA;

○ Measuring accuracy 1%;

○ wear a cable type, wear copper row, opening a variety of installation methods and sizes;

○ current ratio of 2000: 1;

○ The maximum transmission distance is not more than 20 meters.

Outline

Product model

Note: According to the actual use of the cable and copper specifications and installation of residual current transformer model.

Outline and mounting dimensions (mm)

Scope of usage

Mainly used for power distribution cabinets, distribution box, control the electrical shell and other temperature detection, but also on the bus, busbar and other temperature testing.

The environment used

○ Temperature measurement range: -150 ℃ ~ 250 ℃;

○ Accuracy: ± 2 ℃;

○ Altitude ≤ 3000m;

○ Power frequency withstand voltage 3000V / 1min 50Hz;

○ Mainly used in the detection of residual current in the line;

○ For 0.5KV and below, the frequency of 50Hz;

○ Used with UPTR series monitoring detectors;

○ high precision, anti-interference ability;

○ Ambient temperature -30 ℃ ~ +70 ℃, the daily average of not more than 30 ℃;

○ signal transmission distance ≤ 10m, the standard line length 2m;

○ In line with national standards.